We all know that there are two ways to transport fluid in a large-diameter hose. One is positive pressure, which is the outlet of the power pump. One is negative pressure, that is, at the inlet of the power pump. When the pump is working, a vacuum is formed inside the pump body. Because of the atmospheric pressure, the fluid is pressed into the tube body for movement. Of course, according to the popular saying, the fluid is sucked into the large diameter. Inside the hose. Because of the presence of external pressure, large-diameter hoses are sometimes sucked up, causing blockage of the pipeline. So how can a large diameter hose not be flattened?

1. Be sure to determine the working pressure of the large-diameter hose or the lift of the entire pipeline.

2. Determine the structure according to the caliber and length of the large-diameter hose after determining the working pressure or after the head.

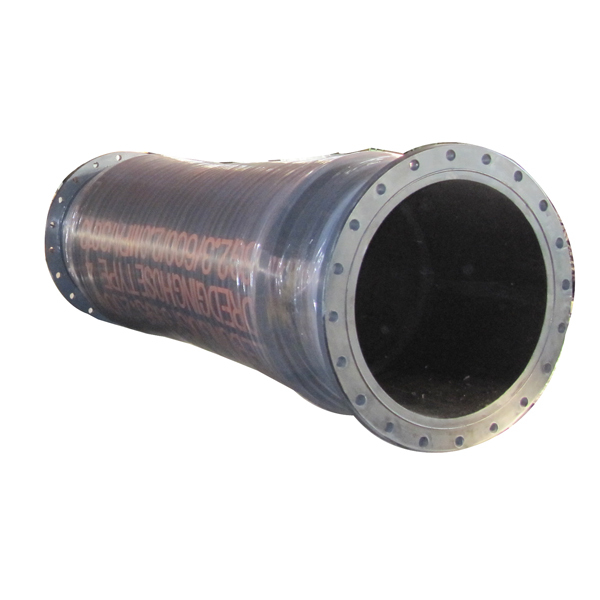

3, the structure of the negative pressure should use the cord reinforcement layer

4, according to the size and pressure of the caliber using a suitable spiral wire reinforcement layer, which is the steel wire skeleton

5. The higher the pressure, the larger the wire diameter of the wire, and the smaller the distance between the spiral wires.

6. Large-diameter large-diameter hoses should be equipped with steel rings when the pressure is negative. The spacing of the general steel rings is 500 mm.

7. The rubber material should be made of synthetic rubber with high rubber content to increase or adhesion.

8. To transport different fluids, it is necessary to select synthetic rubber with different characteristics. For example, large-diameter water hoses and buried hoses should use natural rubber. Large-diameter sand suction hoses should use wear-resistant rubber. Large-diameter oil-resistant hoses should use NBR rubber, large diameter. Water-cooled cable hose uses EPDM rubber, large-diameter flexible hose uses Ding Duo rubber, etc.

To achieve the above points, the large-diameter hose will not be crushed when it is used under negative pressure.