First, TPU product awareness

TPU full name thermoplastic polyurethane. TPU is a polymer containing a large number of carbamate groups (-NHCOO-) on a polymer structure, mainly prepared by reacting a polyol, a stretching agent and a dihydrogenate. TPU has long been widely used in people’s daily lives.

TPU products are usually granular, and have good reworkability. The thermoplastics are processed by injection, extrusion, calendering, blow molding, molding, spinning, and the like. Among them, injection molding and extrusion molding applications account for up to 70% or more. And TPU can also be used to make elastic fibers, synthetic leather resins, and adhesives. Therefore, the application range of polyurethane elastomer is very wide. TPU products and comprehensive performance are outstanding. The application is almost all fields. It is a new generation of engineering plastics and is one of the economical and recyclable environmentally friendly plastic elastomers.

Second, TPU product features:

1. Excellent wear and tear resistance.

2. It has anti-hydrolysis and antibacterial effects.

3. Excellent cold resistance and tortuosity.

4. It is a green plastic material with flame retardant and oil resistant properties.

5. Due to the excellent processing characteristics and the valuable characteristics of rubber and plastic, it is incomparable to the same type of plastic.

Third, the scope of application of TPU products

Third, the scope of application of TPU products

Injection level: auto parts, machine parts, electronic parts, sports shoes, shoe soles, women’s shoes, rollers, straps, toys, sports protective gear, special protective gear, special rubber, animal ear tags, And other plastic products.

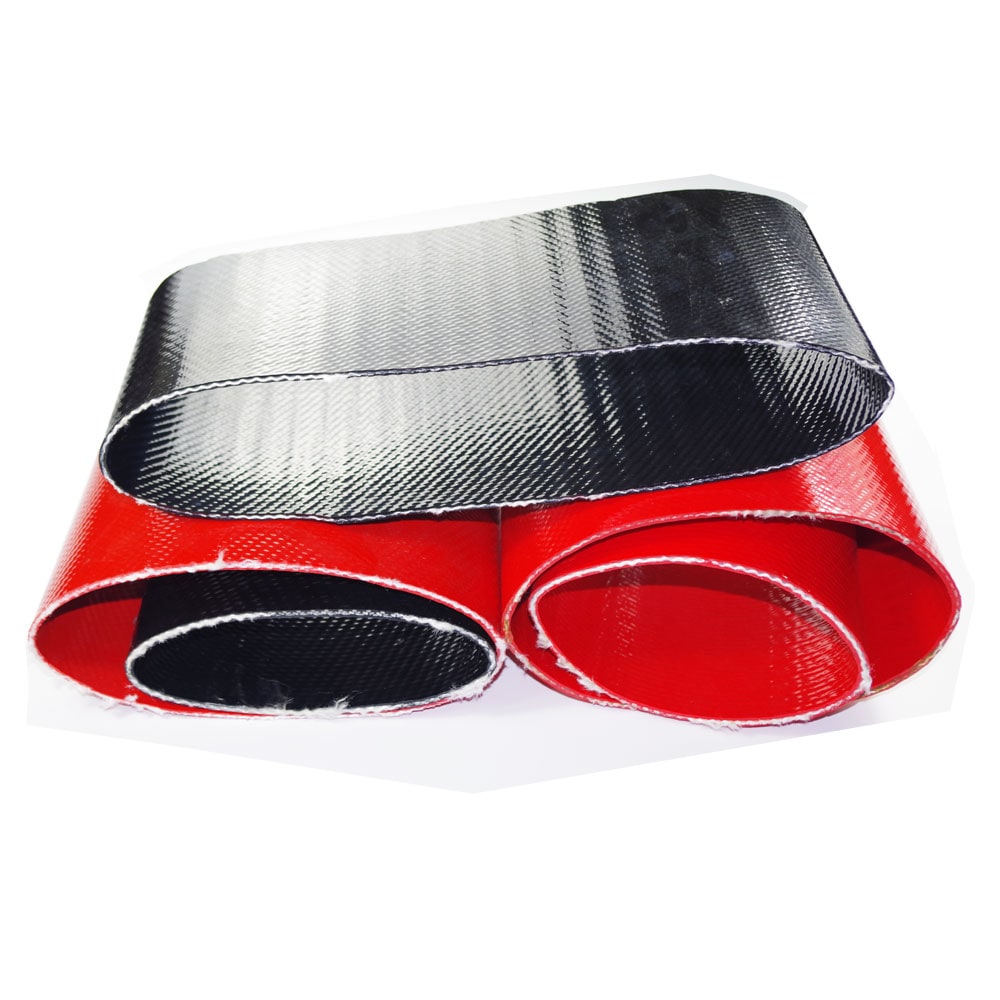

Extrusion grade: wire and cable, pipe, film, sheet, fabric, clothing nail, shoulder strap, and others.

Blow molding grade: plastic bottles, water hoses, sports shoes, air cushions, toys, etc.

Fourth, product use precautions

Fourth, product use precautions

(1) Storage

TPU thermoplastic polyurethane elastomer is easy to absorb moisture in the air, so it should be kept dry during storage. The packaging method is 25 kg bag, which needs to be sealed before and after use. The recommended storage temperature is 20 °C ~ 30 °C, and the relative humidity is 50%.

Because TPU is a moisture-absorbing material, it must be thoroughly dried before removing water. Otherwise, there will be water patterns and bubbles in the finished products, and the most important effects will be greatly reduced in various physical aspects. The baking temperature is from 90 °C to 110 °C for about 3 to 5 hours, and it should not be too thick to avoid the drying effect.

(2) baking recommended temperature

Below 95A, baking temperature is 90 °C ~ 100 °C, baking time is about 3 ~ 5 hours.

Above 95A, baking temperature is 100 °C ~ 110 °C, baking time is about 3 ~ 5 hours.